Interpretation of the Alvatech Geomembrane Technical Data Sheet

November 08, 2021

The ALVATECH Geomembrane Data Sheet contains a list of standarized tests that try to reproduce, in a laboratory, the different requests that the geomembrane will have in a real application; whether it’s a landfill, a reservoir or a heap leach pad, some common high demand geomembrane applications.

Geomembrane Properties

The different properties of the Geomembrane are classified into 3 groups to make the information easier to understand (Technical Data Sheet)

- Raw material used.

- Mechanical Properties: Traction, tearing and puncturing.

- Durability Properties: OIT, HPOIT and STRESS CRACKING show us how the antioxidants behave in our geomembrane.

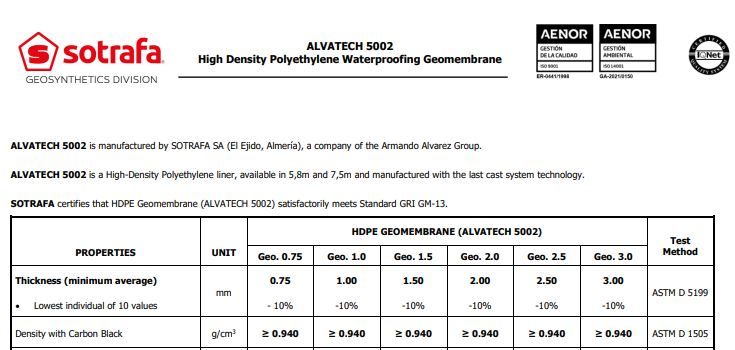

RAW MATERIAL

Polyethylene geomembranes are manufactured with a minimum of 97% virgin polyehtylene raw material and 2-3 additives. These additives are carbon black (2-3%) and antioxidants (0.50-1.00%). With carbon black we can stabilize the geomembrane (preventing it from decomposing quickly), especially from ultraviolet radiation, while with antioxidants we can prevent the creation of free radicals and increase durability.

| We found two key parameters in the technical sheet; Density and Flow Index |

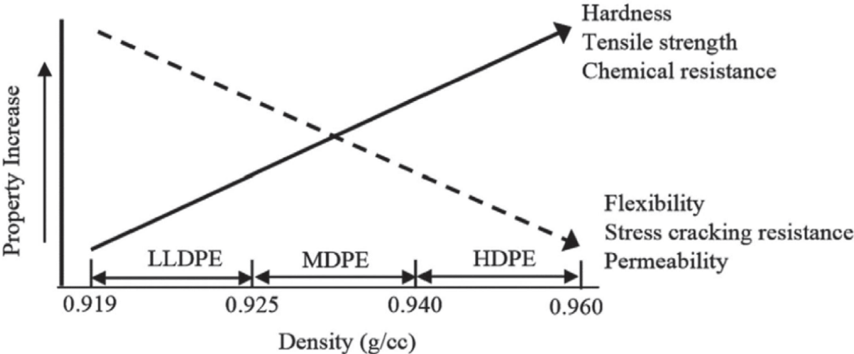

Density tell su if we are dealing with a low density (<0.939 g/cc) or a high density (0.940 – 0.954 g/cc). Both products have different chemical resistance and different mechanical properties which makes them more or less suitable for the desired application.

For its part, the Fluidity Index helps us to interpret how the raw material will behave during the manufacturing process. Higher flow index means that we are dealing with a less viscous material (> MFI < viscosity). At SOTRAFA we have the best technology for the manufacture of geomembranes by Flat Die Extrusion. This allow us to transform polyethylene with very high flow rates (less viscosity) at a lower temperature, which results in a final product that has had less stress when transformed and welds more easily.

MECHANICAL PROPERTIES

They are summarized in tensile, tear and puncture properties. As we wish to be completely transparent with our information, at SOTRAFA we show in parentheses the minimum values required by the standard. Consequently, ALVATECH Geomembranes comfortably exceed the values required by the main regulations worldwide.

Within the tractions, we find the following parameters:

- Traction at break

- Elongation at break

- Traction at yield point or yield point

- Elongation at yield point

A “dumbbell type” test tube is used for this test.

Tensile strength is the maximum stress that the material can withstand. For its part, the traction at the yield point is the effort that the material can resist without permanently becoming deformed. While the first gives us information on the quality of the transformation, the second is useful as a design parameter.

At SOTRAFA we express values in Europe in Megapascals or N/mm2 as indicated by the different European regulations. In America the values are expressed in kN/m. The elongations are expressed in %.

- Puncture Resistance

In this case, the values are simply expressed in kN. The size of the punch is very different in the case of the ASTM and the ISO test; the latter one being much larger.

- Tear Resistance

Because it is done with a V-shaped test tube, the values of this test are expressed in N/mm.

DURABILITY PROPERTIES

Antoher key factor in geomembranes is trying to predict the lifespan of our geomembrane. Degradation of a geomembrane can occur by;

- UV degradation,

- Thermal degradation (the higher the temperature the earlier degradation occurs),

- Chemical degradation,

- By oxidation (creation of free radicals).

In order to estimate the amount of antioxidants in our geomembrane, and therefore its long-term behavior, we use the following standardized tests:

- OIT, Time of Induced Oxidation. When tested at 200 degress Celsius, it informs us of the amount of primary antioxidants (secondary antioxidants such as HALS disappear at more than 150ºC). Basically, these protect our geomembrane during the manufacturing process and subsequent welding on site. This test is measured in minutes (time in which free radicals begin to released).

- HP-OIT is made at a lower temperature, 150 degrees, but with higher pressure. This show us the secondary antioxidants that will give long-term protection against thermal and ultraviolet degradation.

Very high initial values of OIT and HP-OIT do not necessarily guarantee a high durability of the geomembrane. We have verified how geomembranes with very high initial HPOIT values break down very quickly and geomembranes with lower initial values last much longer.

It is important to know the compatibility of the resin used within the antioxidant package. This “recipe” is part of the manufacturer’s Know-How. The key is to know how that pack of antioxidants is going to behave over time; hence the need to work with a top quality and experienced geomembrane manufacturer.

In our Laboratory we try to simulate in an accelerated way the durability of our geomembrane, effectively, how long does it take for our geomembrane to begin to degradate. A geomembrane is considered to have finished its useful life when its mechanical properties are below 50% of the initial ones.

STRESS CRACKING

High-density polyethylene is one of the polymers with a known high chemical resistance. Its weakness is that, being very crystalline, it is susceptible to stress cracking. Resins have evolved a lot in recent years so that for common applications a high quality HDPE Geomembrane should not have stress cracking problems. The test consists of immersing proportional to the thickness and tensioned with a weight. American regulations require a minimum value of 500 hours for this test. At SOTRAFA we have formulations for special applications that far exceed this figure.

THERMAL AGEING

Through this test we carry out an accelerated ageing of the geomembrane to see how it would behave over time. As we know, temperature is a great catalyst for degradation. We place a sample of geomembrane in an oven specifically approved for this test, at 85 degrees for 90 days. After these 90 days we carry out an OIT and HP-OIT test:

- Standard-OIT=> 55%

- HP-OIT=> 80%

The sample has to retain 55% of the Standard OIT or 80% of the HP-OIT.

UV AGEING

In this case we try to simulate the effect of solar radiation on our geomembrane in an accelerated way. We introduce samples into a chamber equipped with UV fluorescent lamps and subject them to a thermal cycle for 1600 hours (approximately 67 days). Once the cycle is complete, we carry out an HP-OIT test, in this case the standard OIT is not made, and the sample must retain at least 50% of the initial value.

At SOTRAFA we have the best technology available, we use only the best resins and additives and have extensive knowledge of the behaviour of different polyethylene formulations.

TESTING FREQUENCIES

At SOTRAFA we follow the recommendation of the GRI (testing frequencies table) regarding the minimum testing frequencies. It is essential to have an adequate testing system in place to avoid unwanted alterations.